Tianjin Yuantai Derun Group JCOE Φ 1420 large straight seam sewing machine was put into operation to fill the gap in Tianjin market

Tianjin Yuantai Derun Group JCOE Φ 1420 large straight seam sewing machine was put into operation to fill the gap in Tianjin market

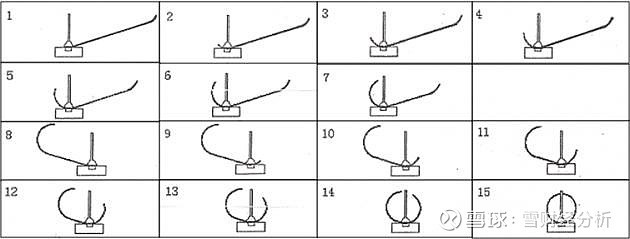

JCOE is a pipe making technology for the production of large diameter thick wall steel pipes. It mainly adopts the production process of double-sided submerged arc welding. The products go through multiple processes such as milling, pre bending, bending, seam closing, internal welding, external welding, straightening, and flat end. The forming process can be divided into N+1 steps (N is a positive integer). The steel plate is automatically fed laterally and bent according to the set step size to realize the numerical control progressive J-C-O forming. The steel plate enters the forming machine horizontally, and under the push of the feeding trolley, the first stage of multi-step bending with N/2 steps is carried out to realize the "J" forming of the front half of the steel plate; In the second stage, firstly, the steel plate formed by "J" shall be sent to the specified position in the transverse direction rapidly, and then the unformed steel plate shall be bent in multiple steps of N/2 from the other end to realize the forming of the second half of the steel plate and complete the forming of "C"; Finally, the lower part of the "C" type tube blank is bent once to realize the "O" forming. The basic principle of each stamping step is three-point bending.

JCOE steel pipes play an important role in large-scale pipeline projects, water and gas transmission projects, urban pipe network construction, bridge piling, municipal construction and urban construction. In recent years, as a new type of energy-saving and environmental protection building system, steel structure buildings are known as "green buildings" in the 21st century. In more and more high-rise and super high-rise building design schemes, steel structures or steel concrete structure systems are preferred, and large-span buildings actively use spatial grid structures, three-dimensional truss structures, cable membrane structures, and prestressed structural systems. These have enabled steel pipes to gain more application scenarios in building projects, while the demand for steel pipes with large diameter and super thick walls has also increased significantly.

Tianjin Yuantai Derun Group JCOE Φ The range of specifications and calibers available for 1420 unit is Φ 406mm to Φ 1420mm, and the maximum wall thickness can reach 50mm. After being put into production, it will make up for the gap in the Tianjin market for such products, which can greatly shorten the order period for super large diameter, super thick wall structure round pipe and square pipe products. The double-sided submerged arc welding large straight seam welded pipe can be directly used for oil and gas transmission. JCOE steel pipe has been widely used in the national "West to East Gas Transmission" project. At the same time, as a structural steel pipe, it can be used in the construction of super high-rise steel structure projects. In addition, the "round to square" process can be used to process it into super large diameter, super thick wall rectangular steel pipe, which can be used in the manufacturing of large amusement facilities and heavy machinery equipment.

The "round to square" unit independently developed by Tianjin Yuantai Derun Group has a maximum processing diameter of 1000mm × 1000mm square tube, 800mm × 1200mm rectangular pipe, with a maximum wall thickness of 50mm, has the processing capacity of super large diameter and super thick wall rectangular pipe, which has been successfully supplied to the domestic market up to 900mm × 900mm × 46mm, maximum outlet 800mm × 800mm × 36mm super large diameter and super thick wall products meet various complex technical requirements of users at home and abroad, including 400mm rectangular tubes × 900mm × 30mm products also represent the leading level of "round to square" process at home and abroad.

Wuhan Greenland Center, the world's third tallest building - a super high-rise landmark skyscraper in Wuhan, China with a design height of 636 meters - is a representative project of super high-rise steel structure supplied and served by Tianjin Yuantai Derun Group.

After many years of process improvement, the outer arc of the large-diameter ultra thick wall rectangular tube produced by the "round to square" process of Tianjin Yuantaiderun Group has successfully overcome the defects prone to cracks during the round to square bending process and the difficulties in controlling the flatness of the tube surface during the "deformation" process, which can meet the requirements of relevant standards at home and abroad for products and customers' special technical parameter control requirements. The products are widely praised in key projects exported to the Middle East, In China, it is also possible to basically replace the "box column" products in the original assembled steel structure enterprises. The square tube products have only one weld, and their structural stability is far better than that of the "box column" products welded by steel plates with four welds. This can be seen in the requirements that Party A specifies the use of "square tube" and prohibits the use of "box column" in some key overseas projects.

In terms of cold bending technology, Tianjin Yuantaiderun Group has accumulated for nearly 20 years and is able to customize profiled structural steel pipes according to customer requirements. The picture shows a customized "octagonal steel pipe" for a large amusement park in China. Because the design parameters need to be cold bent and formed at one time, the diameter and wall thickness requirements of this product have been inquired by major domestic manufacturers for nearly three months. Finally, only Tianjin Yuantaiderun Group met its various requirements, and successfully produced nearly 3000 tons of products and completed all the supply services of the project alone.

It is the firm marketing strategy of Tianjin Yuantaiderun Group to take the "customization" route towards the market. For this reason, Tianjin Yuantai Derun Group continues to make efforts with the ultimate goal of "all square and rectangular tube products must be able to be produced by Yuantai". Guided by the market, it insists on investing more than 50 million yuan every year in the research and development of new equipment, new molds and new processes. At present, it has introduced intelligent tempering equipment, which can be used to produce external arc right angle square tubes for glass curtain wall projects, or conduct annealing stress relief or hot bending processing on square tubes, It greatly enriches the processing capacity and the range of products available, and can meet customers' one-stop procurement needs for square and rectangular tubes.

The market advantage of Tianjin Yuantai Derun Group is that there are many molds, complete varieties and specifications, and fast delivery cycle of conventional non-standard orders for square and rectangular pipe units. The side length of square steel pipes is from 20mm to 1000mm, and the specification of rectangular steel pipes is from 20mm × 30mm to 800mm × 1200mm, the wall thickness of the product is from 1.0mm to 50mm, the length can be 4m to 24m, and the sizing accuracy can be two decimal places. The sizing of the product increases our warehouse management difficulty and management cost, but users will no longer need to cut and weld the product, greatly reducing users' processing costs and material waste. This is one of our innovative practices facing the market and focusing on customers, It will also be maintained for a long time; Through the research and development of new equipment and the introduction of new processes, in addition to conventional square and rectangular pipes, it can also produce various non-standard, special-shaped, multilateral special-shaped, right angle and other structural steel pipes; Large diameter and thick wall structure pipe products have been added to the new structure pipe equipment, which can Φ 20mm to Φ 1420mm structural round pipe with wall thickness of 3.75mm to 50mm; The spot inventory maintains a full specification of Q235 material from 20 to 500 square meters, and provides a year on year Q235 material inventory. At the same time, it is equipped with a spot inventory of Q355 material above 8000 tons and a year on year Q355 material inventory to meet the customer's order delivery capacity of small batches and urgent construction period.

For the above services, we offer the spot price and order price uniformly and transparently to the market. The spot price updates the latest price every day through the We Media Platform Matrix, and order customers can obtain the tradable price through WeChat applet; The order provides users with one-stop processing, distribution and procurement services, including hot-dip galvanizing processing services, product cutting, drilling, painting, component welding and other secondary processing services, in which hot-dip galvanizing can be customized according to customer requirements, and the zinc layer can be up to 100 microns; It provides one-stop and one ticket logistics distribution services such as highway, railway, waterway transportation and short distance centralized transportation. It can issue transportation invoices or value-added tax invoices for freight at preferential prices. For square and rectangular tube orders, users can realize one-stop unified purchasing and delivery services for steel materials including profiles, welded pipes, etc; Tianjin Yuantaiderun Group has a full set of qualifications, including ISO9001, ISO14001, ISO45001, EU CE, French Bureau of Shipping BV, Japan JIS and other full sets of certification, which can help dealers issue authorization and qualification files, assist partners to directly participate in bidding in the name of the Group, and make differentiated bid accompanying quotations for long-term cooperative customers to lock profits on the basis of confirmed transactions